國(guo)(guo)(guo)(guo)聯研究院成立國(guo)(guo)(guo)(guo)家車用動(dong)(dong)力(li)(li)電(dian)池(chi)(chi)產品質量監(jian)督檢驗中心,打造覆蓋車用動(dong)(dong)力(li)(li)電(dian)池(chi)(chi)產品從電(dian)池(chi)(chi)材料(liao)到電(dian)池(chi)(chi)系統全(quan)產業(ye)鏈條的檢測平臺,全(quan)力(li)(li)提升(sheng)(sheng)車用動(dong)(dong)力(li)(li)電(dian)池(chi)(chi)監(jian)督檢測的科學性、嚴(yan)肅性、權威(wei)性,促進動(dong)(dong)力(li)(li)電(dian)池(chi)(chi)產業(ye)創新能力(li)(li)提升(sheng)(sheng),對增強我國(guo)(guo)(guo)(guo)動(dong)(dong)力(li)(li)電(dian)池(chi)(chi)產業(ye)國(guo)(guo)(guo)(guo)際競爭力(li)(li)、實現高(gao)質量發展,具有重要意(yi)義(yi)。

布局全鏈條,構建檢測驗證平臺

我(wo)國動(dong)力電(dian)池(chi)產業已經進(jin)入加速發(fa)展新階段,急需建(jian)設和提(ti)升動(dong)力電(dian)池(chi)產品試驗檢測能力,覆(fu)蓋動(dong)力電(dian)池(chi)前(qian)期(qi)材料篩選及(ji)設計開發(fa)、中期(qi)整車開發(fa)階段電(dian)池(chi)系統的研(yan)發(fa)以及(ji)后期(qi)動(dong)力電(dian)池(chi)梯次利用和回收(shou)等各(ge)個環節,建(jian)立(li)更(geng)高效、更(geng)準確(que)的動(dong)力電(dian)池(chi)測試技(ji)術(shu)及(ji)更(geng)全面(mian)的動(dong)力電(dian)池(chi)評(ping)價技(ji)術(shu)體系。

2016年(nian)6月,依托國(guo)聯(lian)研究(jiu)院(yuan)成(cheng)(cheng)立的(de)國(guo)家(jia)動(dong)力(li)(li)(li)電(dian)(dian)池創新中(zhong)心(xin),啟動(dong)建(jian)(jian)設動(dong)力(li)(li)(li)電(dian)(dian)池檢(jian)驗測(ce)試評(ping)價平臺(tai),以保障產(chan)業(ye)基礎性技術(shu)供給、促(cu)進我國(guo)動(dong)力(li)(li)(li)電(dian)(dian)池產(chan)業(ye)提升技術(shu)和(he)(he)質(zhi)量(liang)水平為目標(biao),著手打造動(dong)力(li)(li)(li)電(dian)(dian)池關鍵材料、單體(ti)電(dian)(dian)池到電(dian)(dian)池系統全鏈(lian)條(tiao)測(ce)試能力(li)(li)(li),形成(cheng)(cheng)動(dong)力(li)(li)(li)電(dian)(dian)池功能特性、耐久性、環境適應性、安全可靠性等(deng)技術(shu)標(biao)準體(ti)系,建(jian)(jian)設設計(ji)驗證(zheng)、產(chan)品檢(jian)測(ce)和(he)(he)風險評(ping)估等(deng)能力(li)(li)(li)。2019年(nian)2月,工信部(bu)(bu)推(tui)薦籌建(jian)(jian)國(guo)家(jia)動(dong)力(li)(li)(li)電(dian)(dian)池產(chan)品質(zhi)量(liang)監(jian)督檢(jian)驗中(zhong)心(xin),2019年(nian)6月完(wan)成(cheng)(cheng)大部(bu)(bu)分軟硬件和(he)(he)管理體(ti)系建(jian)(jian)設,2020年(nian)提交籌建(jian)(jian)申請(qing)和(he)(he)籌建(jian)(jian)認(ren)證(zheng),并于2020年(nian)12月籌建(jian)(jian)完(wan)成(cheng)(cheng)正式成(cheng)(cheng)立國(guo)家(jia)車用動(dong)力(li)(li)(li)電(dian)(dian)池產(chan)品質(zhi)量(liang)監(jian)督檢(jian)驗中(zhong)心(xin)。

創新促發展,提升檢測驗證技術水平

針對(dui)行業發展需求,國聯(lian)研究院(yuan)通過(guo)管理創新、技(ji)術創新,促進在動力電(dian)池(chi)關鍵材(cai)料、單體電(dian)池(chi)、電(dian)池(chi)系統設計驗(yan)證、產品檢測和風險評估以及功能特性(xing)、耐久性(xing)、環境(jing)適應性(xing)、安全(quan)可靠性(xing)等技(ji)術標準(zhun)體系方面,全(quan)面提(ti)升技(ji)術水(shui)平(ping)。

高(gao)比(bi)能動力電(dian)池其材(cai)料熱(re)穩(wen)定(ding)性(xing)相對(dui)較(jiao)差,受環(huan)(huan)境(jing)(jing)溫度影響較(jiao)大,在波動度為±0.5℃、均勻度為±2℃以內(nei)(nei)的(de)環(huan)(huan)境(jing)(jing)箱(xiang)內(nei)(nei),放(fang)(fang)置(zhi)(zhi)于不(bu)同(tong)位(wei)置(zhi)(zhi)仍會帶來電(dian)池平(ping)行樣品(pin)的(de)容(rong)(rong)量偏差(≦2%左右)。為了(le)保障測(ce)試(shi)數據準確性(xing)和(he)一致(zhi)性(xing),測(ce)試(shi)人員積極研究(jiu)思考,將熱(re)特(te)性(xing)理論應用于實踐(jian),提出用換(huan)熱(re)系數評價不(bu)同(tong)位(wei)置(zhi)(zhi)的(de)溫度效果(guo)差異(yi),組(zu)建測(ce)試(shi)小(xiao)組(zu)和(he)計(ji)算小(xiao)組(zu),針對(dui)不(bu)同(tong)類(lei)型的(de)環(huan)(huan)境(jing)(jing)實驗箱(xiang),根據風(feng)(feng)道(dao)、風(feng)(feng)速、風(feng)(feng)向重新設(she)計(ji)樣品(pin)擺放(fang)(fang)位(wei)置(zhi)(zhi),電(dian)池平(ping)行樣品(pin)的(de)容(rong)(rong)量檢測(ce)差異(yi)可控(kong)制在1%以內(nei)(nei),并以此成果(guo)申報專利1項(xiang)。

在(zai)與(yu)電池(chi)生產企(qi)業、上游車企(qi)溝通過程中(zhong),客戶十分(fen)關注用(yong)(yong)于熱(re)管理設計(ji)的電池(chi)熱(re)物(wu)性參(can)數(shu)——導熱(re)系(xi)數(shu),但目(mu)前沒有快(kuai)速(su)準確的檢測(ce)手(shou)段。為此,國(guo)聯研究(jiu)院積極組織攻關,組建試驗(yan)(yan)開(kai)發小組、理論計(ji)算(suan)(suan)小組,開(kai)展(zhan)測(ce)量(liang)方(fang)法(fa)研究(jiu);大膽(dan)設計(ji)實(shi)驗(yan)(yan),制備多款不(bu)同體系(xi)電池(chi),采用(yong)(yong)理論計(ji)算(suan)(suan)模擬(ni)數(shu)據與(yu)測(ce)量(liang)實(shi)驗(yan)(yan)數(shu)據對(dui)比(bi)驗(yan)(yan)證方(fang)式,開(kai)展(zhan)檢測(ce)方(fang)法(fa)研究(jiu)。通過試驗(yan)(yan),嚴(yan)謹求證,最終獲得一種快(kuai)速(su)實(shi)現導熱(re)系(xi)數(shu)測(ce)量(liang)的方(fang)法(fa),實(shi)測(ce)數(shu)據與(yu)理論計(ji)算(suan)(suan)數(shu)據偏差在(zai)3%~5%,圓滿達成(cheng)預期目(mu)標,成(cheng)果(guo)申報(bao)國(guo)內(nei)發明專利(li)2項(xiang)、PCT國(guo)際專利(li)1項(xiang)。

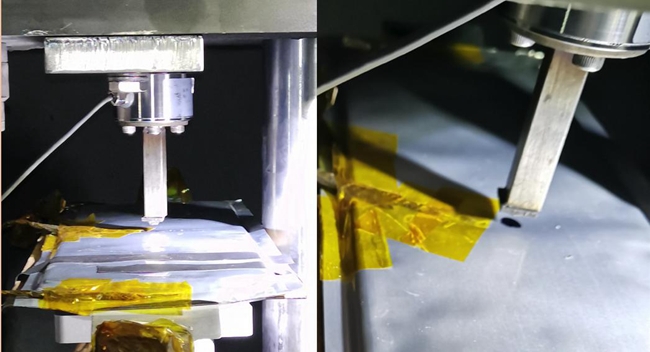

對于(yu)強(qiang)制內(nei)短(duan)(duan)(duan)路測(ce)(ce)(ce)試(shi)(shi),大多(duo)采用幾(ji)家電(dian)(dian)池(chi)檢測(ce)(ce)(ce)單(dan)(dan)位聯(lian)合的方(fang)式進(jin)(jin)行(xing),一(yi)家檢測(ce)(ce)(ce)單(dan)(dan)位僅完成強(qiang)制內(nei)短(duan)(duan)(duan)路測(ce)(ce)(ce)試(shi)(shi)方(fang)法(fa)(fa)的一(yi)項(xiang)或幾(ji)項(xiang)步(bu)驟,不能完成全過(guo)程(cheng)項(xiang)目。國聯(lian)研究院對此開展了大量(liang)電(dian)(dian)池(chi)強(qiang)制內(nei)短(duan)(duan)(duan)路測(ce)(ce)(ce)試(shi)(shi)實驗,對滿電(dian)(dian)態被測(ce)(ce)(ce)試(shi)(shi)電(dian)(dian)池(chi)樣品(pin)進(jin)(jin)行(xing)精(jing)準拆(chai)解,保證被擠壓極(ji)片完整;植(zhi)入L型(xing)鎳顆粒(li),通過(guo)十字交叉法(fa)(fa)精(jing)確定(ding)位L型(xing)鎳顆粒(li)并(bing)封裝還原(yuan),實現(xian)高質量(liang)還原(yuan)拆(chai)解電(dian)(dian)池(chi);通過(guo)伺服(fu)電(dian)(dian)機和壓力(li)實時(shi)回(hui)饋系統精(jing)確控制,精(jing)確定(ding)位擠壓1mm L型(xing)鎳顆粒(li),強(qiang)制引發(fa)電(dian)(dian)芯內(nei)短(duan)(duan)(duan)路,監測(ce)(ce)(ce)與記錄全過(guo)程(cheng)數據,最終全面(mian)掌(zhang)握(wo)了強(qiang)制內(nei)短(duan)(duan)(duan)路測(ce)(ce)(ce)試(shi)(shi)全過(guo)程(cheng)技術。

拓展檢測項目,提升行業服務水平

面向(xiang)動力(li)電(dian)(dian)池(chi)(chi)材(cai)料、電(dian)(dian)池(chi)(chi)及電(dian)(dian)池(chi)(chi)系(xi)統(tong)全(quan)(quan)(quan)(quan)產業鏈條,質(zhi)檢(jian)(jian)中(zhong)(zhong)心設立(li)材(cai)料分析實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi)、動力(li)電(dian)(dian)池(chi)(chi)實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi)、電(dian)(dian)池(chi)(chi)系(xi)統(tong)實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi)、可(ke)靠(kao)性實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi)、安全(quan)(quan)(quan)(quan)性實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi)和(he)計算仿真實(shi)(shi)(shi)驗(yan)(yan)(yan)室(shi),獲(huo)得(de)CMA&CAL&CNAS認(ren)證、TUV北德ECE-R100及UN38.3檢(jian)(jian)測資(zi)質(zhi),覆(fu)蓋標(biao)準(zhun)77項(xiang),承栓項(xiang)目292項(xiang)。其中(zhong)(zhong)關(guan)鍵材(cai)料及其原材(cai)料檢(jian)(jian)驗(yan)(yan)(yan)標(biao)準(zhun)31項(xiang),電(dian)(dian)池(chi)(chi)模塊、單(dan)體及其零(ling)部(bu)件(jian)檢(jian)(jian)驗(yan)(yan)(yan)標(biao)準(zhun)27項(xiang),電(dian)(dian)池(chi)(chi)系(xi)統(tong)及其管理系(xi)統(tong)檢(jian)(jian)驗(yan)(yan)(yan)標(biao)準(zhun)19項(xiang)。可(ke)實(shi)(shi)(shi)現動力(li)電(dian)(dian)池(chi)(chi)全(quan)(quan)(quan)(quan)產品層級、全(quan)(quan)(quan)(quan)生命周期的綜合(he)性測試驗(yan)(yan)(yan)證,具備歐盟動力(li)電(dian)(dian)池(chi)(chi)安全(quan)(quan)(quan)(quan)檢(jian)(jian)測和(he)航空運(yun)輸檢(jian)(jian)測能(neng)力(li),同時(shi)也覆(fu)蓋儲能(neng)電(dian)(dian)池(chi)(chi)標(biao)準(zhun)及國(guo)外相關(guan)通用標(biao)準(zhun)。

目前質檢(jian)中(zhong)心服(fu)務客戶超(chao)過80家,檢(jian)測樣品數量(liang)上(shang)萬個,客戶覆蓋國內外知名整(zheng)車(che)、電(dian)池(chi)企(qi)(qi)(qi)業(ye)(ye)(ye)、檢(jian)測企(qi)(qi)(qi)業(ye)(ye)(ye)、高(gao)校及科(ke)(ke)研(yan)院(yuan)所,包(bao)括一汽、東風等整(zheng)車(che)企(qi)(qi)(qi)業(ye)(ye)(ye),力(li)神、蜂巢(chao)、遠景等電(dian)池(chi)企(qi)(qi)(qi)業(ye)(ye)(ye),十(shi)八所、中(zhong)汽研(yan)、中(zhong)電(dian)四所等電(dian)池(chi)檢(jian)測企(qi)(qi)(qi)業(ye)(ye)(ye),清華、國網(wang)電(dian)科(ke)(ke)院(yuan)等高(gao)校和科(ke)(ke)研(yan)院(yuan)所。

面向(xiang)未來,國(guo)聯研究(jiu)院將繼續秉承(cheng)創(chuang)新驅動發(fa)展(zhan)(zhan)理念(nian),加強檢測平臺(tai)建設,立足行業高質量服(fu)務,加大新技(ji)術、新方法及新設備創(chuang)新和攻關(guan)(guan)力(li)(li)度,積極(ji)承(cheng)擔相關(guan)(guan)標準制修(xiu)訂和試(shi)驗驗證工(gong)作,做優做強測試(shi)服(fu)務體系,不斷提升技(ji)術能力(li)(li)和綜合(he)服(fu)務水(shui)平,充分(fen)發(fa)揮國(guo)家質檢中心的國(guo)家隊(dui)和排頭兵(bing)作用,助力(li)(li)新能源汽車(che)產業健康(kang)持續高質量發(fa)展(zhan)(zhan)。